Wadding and hard padding are essential components in a wide variety of industries-from healthcare to textiles to bedding. These nonwoven materials serve critical functions such as cushioning, insulation, and moisture absorption. Whether used in incontinence pads, retail garments, or mattress protectors, their performance directly affects the comfort, hygiene, and durability of the end product.

In this detailed guide, we’ll explore what wadding and hard padding are, how they’re manufactured, where they’re used, and why they’re critical in modern product design and production.

Wadding refers to a soft, fibrous material typically made from natural or synthetic fibers like polyester, cotton, viscose, or blends. It is generally used to provide padding, insulation, or bulk in a product.

Thermal Bonded Wadding: Created by bonding fibers through heat.

Needle-Punched Felt Wadding: Mechanically entangled for strength and structure.

Spray-Bonded Wadding: Adhesive bonding to enhance volume and durability.

Resin-Bonded Wadding: Used for high-compression applications.

p>Hard padding is a rigid or semi-rigid form of wadding, often made from needle-punched felt or high-density fiber blends. It is used when shape retention, compression resistance, or extra support is needed.

High tensile strength

Excellent compression resistance

Breathable and moisture-wicking

Retains shape over time

| Feature | Wadding | Hard Padding |

|---|---|---|

| Texture | Soft and flexible | Firm and structured |

| Use Case | Insulation, softness | Support, shape retention |

| Manufacturing | Thermal or chemical bonding | Needle punching (mostly) |

| Thickness & Density | Low to medium | Medium to high |

| Applications | Quilts, jackets, bedding | Mattresses, pads, upholstery |

Raw materials such as polyester, viscose, or cotton are selected based on the required performance (e.g., softness, strength, absorption).

Fibers are loosened and aligned using carding machines to form a uniform web.

Multiple carded webs are layered to achieve the desired weight and thickness.

Depending on the product:

Thermal bonding fuses fibers with heat.

Needle punching entangles fibers using barbed needles.

Chemical bonding uses adhesives or resins.

The material is heat-set to stabilize dimensions and then rolled for dispatch or further conversion.

Hard padding is widely used as the absorbent and structural layer in hospital-grade incontinence pads, ensuring:

Maximum moisture absorption

Leak prevention

Skin protection

Used in the inner layers of mattress protectors to offer:

Enhanced durability

Moisture control

Cushioning comfort

Wadding felt is used in:

Jackets and coats for insulation

Shoulder pads for structure

Quilted garments for style and warmth

Hard padding supports structure in:

Sofa cushions

Headboards

Padded furniture elements

Noise and thermal insulation layers in vehicles

Seat backing and roof linings

✅ Lightweight yet strong

✅ Breathable and hypoallergenic

✅ Customizable thickness and density

✅ Cost-effective in bulk production

✅ Environmentally friendly (using recycled fibers)

| Application | Recommended Type |

|---|---|

| Hospital incontinence pads | Needle-punched hard padding |

| Mattress protectors | Thermal bonded wadding |

| Jackets and fashion | Spray-bonded or soft felt |

| Upholstery | High-density hard padding |

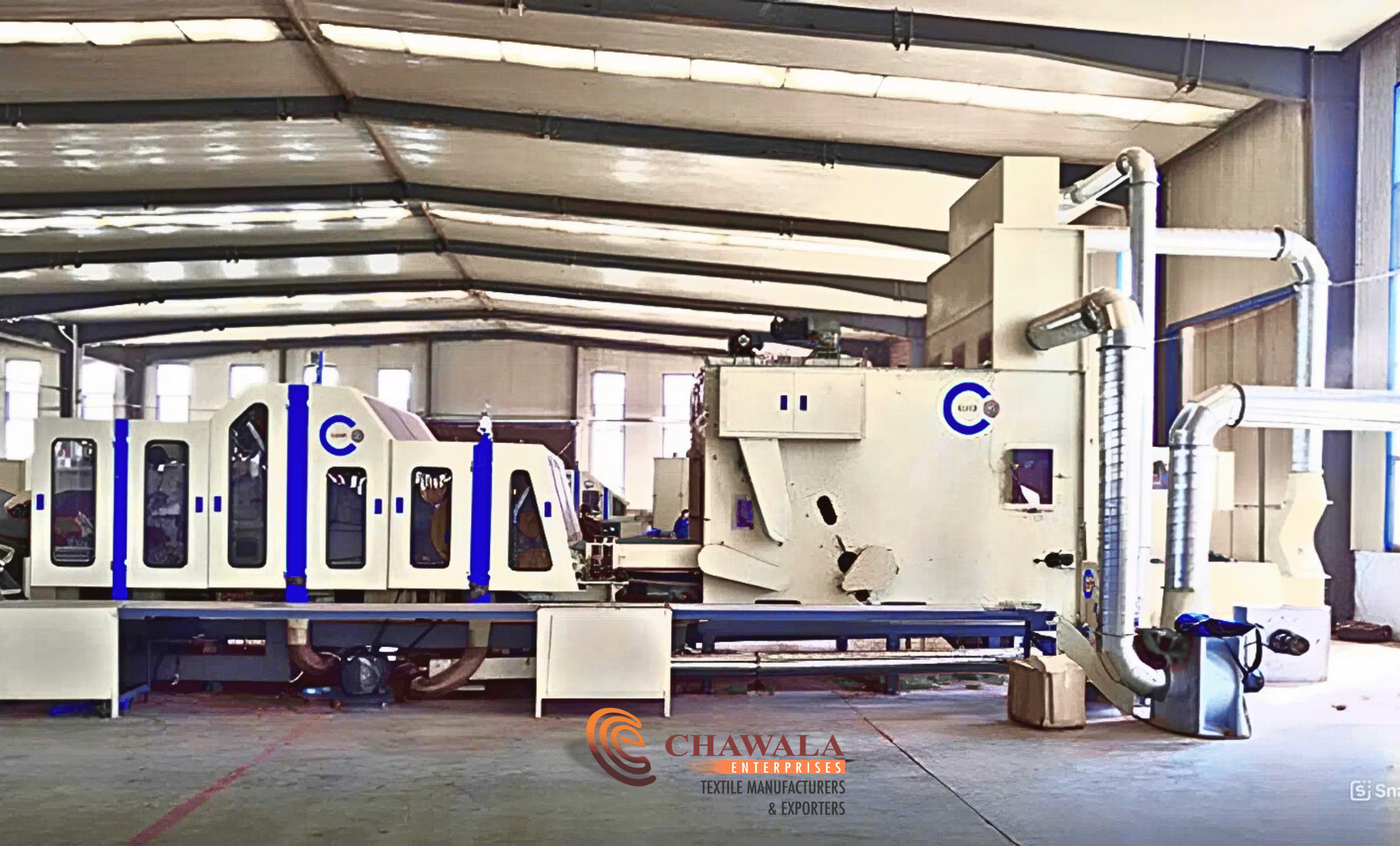

With years of expertise in nonwoven manufacturing, Chawala Enterprises delivers premium-quality wadding and hard padding materials tailored to your specific needs. We offer:

Custom GSM & Thickness

Blends like polyester-viscose or cotton-poly

OEM services for bulk buyers

Strict quality control & certifications

Need a reliable supplier for industrial-grade wadding or hard padding?

? Call us at [Phone Number]

? Email: [Email Address]

? Visit: [Website URL]

Let’s talk about how we can add comfort, structure, and performance to your next product.

Yes, most types of polyester or blended wadding are machine washable and retain their shape after drying.

Absolutely. We offer customized solutions in terms of fiber blend, density, GSM, and dimensions.

Yes, we cater to global clients with reliable logistics and export documentation support.

Nonwoven padding

Needle punched felt

Polyester wadding roll

Quilt batting

Felt insulation

Wadding and hard padding are far more than filler materials-they are essential elements that determine the comfort, hygiene, and durability of modern products. By understanding their types, applications, and benefits, manufacturers can make smarter, more cost-effective material choices.

Ready to enhance your products with premium-grade padding solutions? Contact [Your Brand Name] and experience the difference in quality and support.

We are open from Monday to Saturday / 09:00am – 05:00pm

Address: 3-K.M. Jhumra Road, Khurrianwala, Faisalabad, Pakistan.

Phone: +92-41-4360228 / +92-332-9669191

E-mail: hassan@chawala.com.pk / info@chawala.com.pk